- Overview

- Inquiry

- Related Products

| Specification: | |

| Item | Auto Transfer equipment |

| Control method | Mitsubishi PLC Control |

| PCB size | 50*50*—W350*L1200(mm);2in 1 out |

| Fix Chain Distance | Adjust from 100mm-600mm |

| Transport high | 910±30mm |

| Transmission direction | R→L |

| Power supply | AC220V 50HZ-60HZ |

| Air pressure | 5—7kg/cm2 |

| Dimension | 1100L*1300W*1200H(mm) |

| Weight | 200KG |

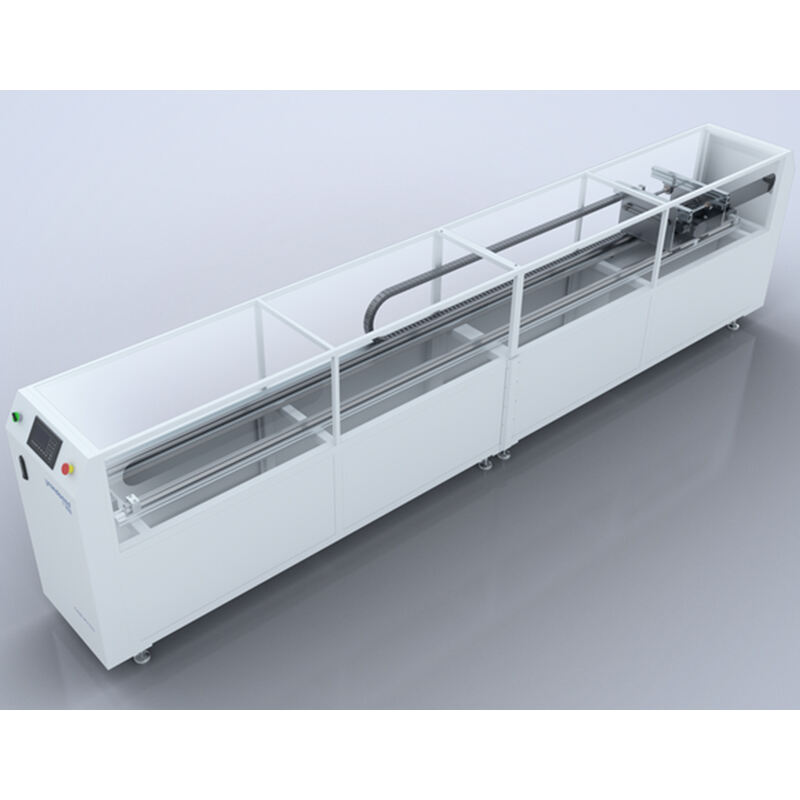

The parallel transfer machine GSD-PY331 is a parallel transition conveying equipment used between two conveyor lines with deviations between the two ends or the center line of an automated production line. It mainly consists of several parts such as frame components, transfer trolley, conveying guide rail, and electrical control.

1. Using one or two mobile trolleys to move back and forth between two specific positions, in order to achieve automated and perfect docking between SMT or plug-in equipment and logistics system equipment, such as converging or diverting transportation in specific situations such as 1 in 2 and 2-in-1 or 3-in-1.

2. Applicable: A production mode that automatically transfers workpieces (PCBs or sheet materials) to the next specific equipment through offset translation connection between multiple production lines (DIP, SMT or other processes).

3. Energy saving solution for SMT process: Only one reflow soldering machine is needed for 2 to 4 SMT wires, or only one wave soldering machine is needed for 2 plug-in wires

Process Configuration Table of GRANDSEED Parallel Transfer Machine GSD-PY331

PCB board width: 50-300MM adjustable

Input power supply: AC220V/50-60HZ (independent electrical box control)

Conveying height: 750+/-20mm

Conveyor motor: Zhongda motor (ZD)

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

LT

LT

SR

SR

SK

SK

VI

VI

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

BE

BE

MK

MK

AZ

AZ

BN

BN

LA

LA

MN

MN

NE

NE

TA

TA

UZ

UZ

XH

XH